butt is a part of a car engine, mechanical component that is located in the internal combustion engines of cars. Its mission is to avoid compression losses inside the cylinders, by closing the upper part of these devices. It can also contain in its interior the intake and exhaust valves, the camshaft, the crankshaft with the connecting rods and the pistons. Meet the cylinder head parts and their functions. Generally, these parts are made of cast iron, in order to offer greater durability and economy, despite being heavier. They are also made of aluminum alloy, being a less heavy material.

What is the butt?

The cylinder head is a piece made of metal that is installed in the block of an internal combustion engine of a vehicle to close the cylinders at one end.. In an engine, the upper part of the cylinder is closed with a part known as the cylinder head. The cylinder head is bolted to the top of the cylinder block. This gasket is covered by a head gasket. It’s a combustion chamber, spark plugs, and sometimes valves (on heads I and F).

In most engines, the cylinder head contains conductors that supply air and fuel to the cylinders and also allow exhaust gases to escape. The cylinder head is a piece that is usually made of gray iron or aluminum alloy. Aluminum offers the advantages of light weight and high thermal conductivity.

cylinder head parts

This piece is composed of the following parts:

- head gasket

- intake and exhaust ports

- head valves

- head combustion chamber

- Plugs

- fuel injectors

- head camshaft

- Additional cylinder head parts

1. Head gasket

It is located between the cylinder head and the engine block. A head gasket is going to bolt into the top of the motor housing. The gaskets work as a seal between the cylinder head and the engine block. The main function is to prevent engine oil and coolant from leaking or mixing.

2. Intake and exhaust ports

The intake and exhaust ports are part of the cylinder head. The intake port ensures that the air circulates through a channel to the cylinder head and the combustion chamber. After the combustion process, gases are removed from the combustion chamber through the exhaust port. This process prevents the build-up of internal pressure, which can lead to an explosion.

3. Head valves

The valves in an engine have the function of closing and opening, with the purpose of stopping or preventing the entry of air and fuel into the combustion chamber. In an internal combustion engine, each cylinder has two valves: the intake valve, which is usually larger, and the exhaust valve, which is smaller in size.

4. Main combustion chamber

The combustion chamber of the head is called the core of the motor. Where the air-fuel mixture is burned so that the energy necessary to run the vehicle occurs. The combustion chamber is manufactured in various designs and sizes. Everything will depend on the engine and application of the car.

5. Spark plugs

The energy is responsible for emanating energy to the combustion chamber to ignite the mixture of air and fuel. The plugs They are pieces that are installed in the cylinder heads and their tips go directly to the combustion chamber. They are usually threaded to ensure a tight seal.

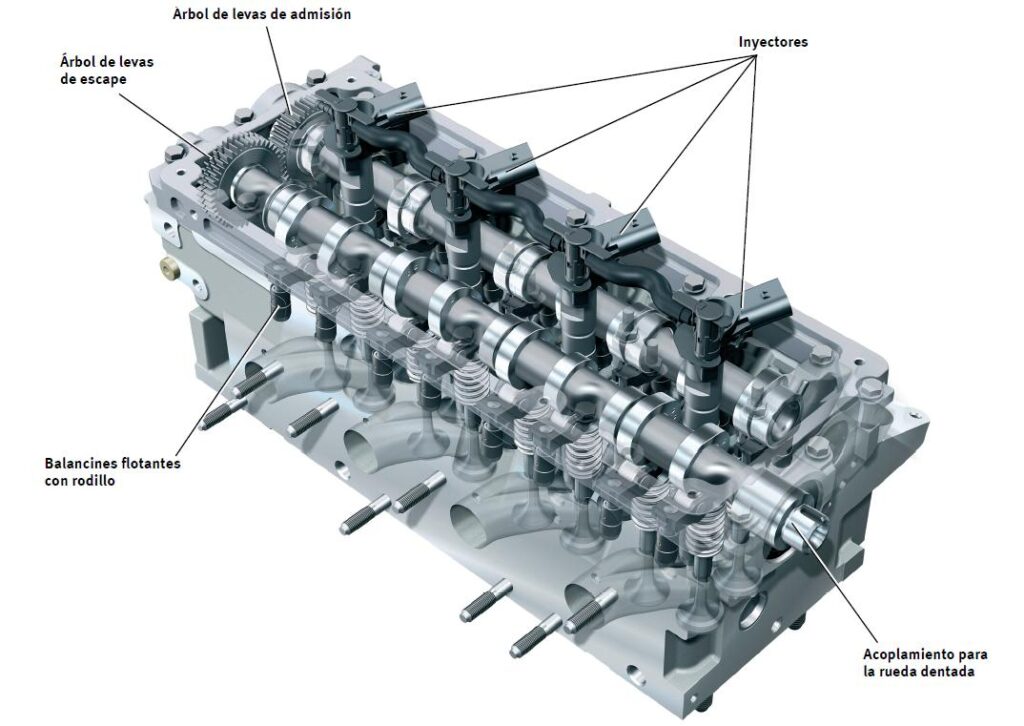

6. Fuel injectors

The fuel injectors can also be found on the cylinder head cover. In a diesel engine, the injectors they induce fuel into the combustion chamber via the injection pump.

7. Main camshaft

The cylinder head is a piece that also contains the camshaft. The camshaft works to open and close the valves. The crankshaft is part of the engine block elements, it uses a belt to drive the camshaft from the cylinder head.

8. Additional cylinder head parts

In addition, the cylinder head has ports responsible for lubricating and cooling the engine. Cylinder head port shapes vary, as do cylinder head designs. The purpose of each type of manufacturing is for each part to work as efficiently as possible.

Cylinder head construction

I know melts away from cylinder block to clean and remove carbon and valve honing. It is done to maintain compression inside the cylinder, a flat gasket is installed between the cylinder head and the cylinder block.

In certain cases, such as racing car engines, a separate head is not used. Although a single piece of cylinder block and head is difficult and expensive to build, and the internal parts of the engine are not very accessible.

Depending on the valve design, the cylinder head may contain camshafts, rocker arms and valves. Its supplied water ways to adjust the valve seat and plug. Mechanically the design details of a detachable stock are possibly the most complicated.

To disassemble the heads of the cylinder head, the following must be considered:

- The inside diameter of the cylinder or linear, must not be distorted by the pull of the clamping bolts.

- The coolant circulation in the cylinder head should be brought as far as possible to the upper end.

- To ensure a gas-tight joint, the retaining bolts must be distributed as evenly as possible around the circumference of each cylinder.

cylinder head function

The cylinder head has a vital function in the car engine. The complicated cylinder head structure has a variety of ports. One of the ports is made to run a part of the engine. Provides the assembly of various components such as: inlet and outlet valves and exhaust ducts, spark plugs, fuel injectors and camshaft. On the other hand, it allows the flow of coolant, oil and combustion gases.

The cylinder block is responsible for absorbing the heat generated by the engine, so it produces cooling to avoid engine problems. It seals the combustion chamber and manages as the engine’s mechanical control center. It also eliminates the compression that results from the combustion pressure process.

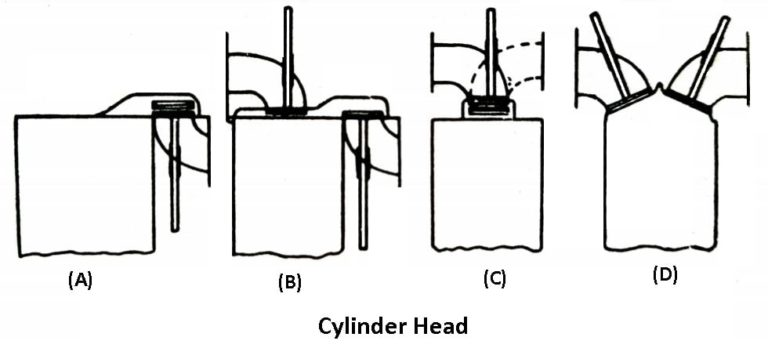

Four cylinder head designs

Four cylinder head designs and the location of the valves can be seen in the figures. And it is described as follows:

In (a) is the popular side valve construction along with all in-line valves, you can see the removable swirl type head. The piston comes very close to the flat position in the cylinder head.

Shown in (b) is the reverse valve construction of the cylinder head that offers good volumetric efficiency, because a large inlet valve can be used and the valve port allows direct access to the orifice.

In (c) you can see the cylinder head with vertical valves in single line that allows the simple push rod and rocker arm.

Shown in (d) is a suitable hemispherical head used in several high-performance designs. In this design, the flame path is short and a domed piston crown can easily provide a high compression ratio.

cylinder head types

Next we are going to know the different types of butt that exist:

- flat head cylinder head

- Overhead valve head

- Overhead camshaft cylinder head

1. Flat head cylinder head

East type of cylinder heads belong to the group that have a single piece of cast iron metal, without mechanical components. On the other hand, they have a simple designthe flat head type of engine cylinder head has its drawbacks.

The valves are located on the sides of the engine block. Which leads to the intake gases moving at an angle of 90º, this produces poor combustion and a low compression ratio. It’s all due to design flaws, the flat head cylinder is not considered common.

These parts are simple to manufacture and need a low cost, the head intervenes so that the coolant circulates more efficiently.. It is lightweight and allows for a compact engine. It can be found in small engines such as those used in lawnmowers, small tractors, and farm vehicles.

2. Overhead Valve (OHV) Cylinder Head

The cylinder heads with overhead valves are complex to manufactureare also known by type I cylinder heads. It includes the parts of the valve train, the spark plugs and the passages for the circulation of intake and exhaust gases.

Engines that have OHV types of cylinder heads tend to perform optimally, everything is due to the location of the valves and the intake ducts. The flow of intake gases works quickly and is smoother due to the design of the paths.

The benefit of fitting this type of cylinder head is that the exhaust ports are more efficient, on the other hand the head does not get hot compared to the flat head type. It also approximates the crankshaft camshaft.

3. Overhead Camshaft (OHC) Cylinder Head

This type of cylinder head accepts parts of the valve train, spark plugs and intake and exhaust ports, and the same cylinder head allows the camshaft. The location of the lea trees on the stock will vary. They may be located in the middle, in the middle of a row of valves, or at the top of the valve.

An OHC cylinder head is available in two configurations namely a single and a double. In a single OHC cylinder head, you have intake and exhaust valves on a single camshaft. In a dual OHC cylinder head it contains two separate camshafts, for the intake and exhaust valve.

Advantages of cylinder and head

There are certain advantages of the aluminum alloy cylinder and head, we will know them below:

- Higher thermal conductivity that is approximately three times that of cast iron.

- The weight is lighter

- Higher compression ratio without detonation due to thermal conductivity.

- Better cooling while the engine is running.

- Higher power output and lower fuel consumption, all because of a higher compression ratio and better cooling effect.

- The engine heats up faster and requires a smaller radiator.

Disadvantages

Also the aluminum alloy cylinder and head has its disadvantages, such as:

- The engine is more expensive due to the fast aluminum alloy.

- It may possibly deform when clamping the studs due to the low modulus of elasticity.

- Due to the greater thermal expansion, a greater clearance is needed between the piston and the cylinder.

- Increased possibility of corrosion by cooling water.

- Sometimes it is necessary to use cast iron valve seats and spark plug inserts.

- Due to intermetallic corrosion between the steel bolts and the aluminum alloy, the cylinder head may stick to the cylinder blocks.

cylinder head applications

Cylinder head applications include the following:

- The cylinder head is integrated into the cylinder block, in many cases it is recurrent in racing cars to achieve a gas-tight joint.

- The detachable head type offers more advantages than the integral construction.

- Although certain heavy-duty engines that require higher amounts of cooling, such as racing cars, can use copper alloys.

conclusion

As mentioned it refers to a removable metal that is installed on top of the cylinder block. Its main function is to close the combustion chamber of the engine from above.

Editorial Gossipvehicle