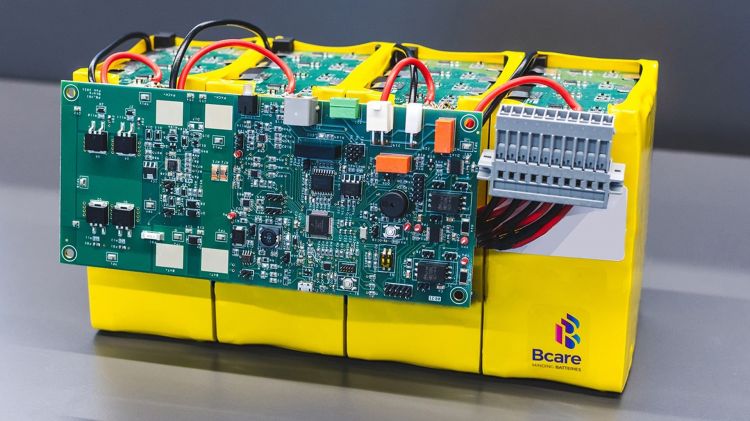

EV batteries play an increasingly important role in energy utilization and storage. The performance of electric cars depends a lot on the capacity of the battery and as they evolve these are increasingly efficient. And in its efficiency it is always important to take care of its thermal state, which makes systems important BTMS.

Here you will learn what BTMS is and its importance for the optimal functioning of electric car batteries.

What is BTM?

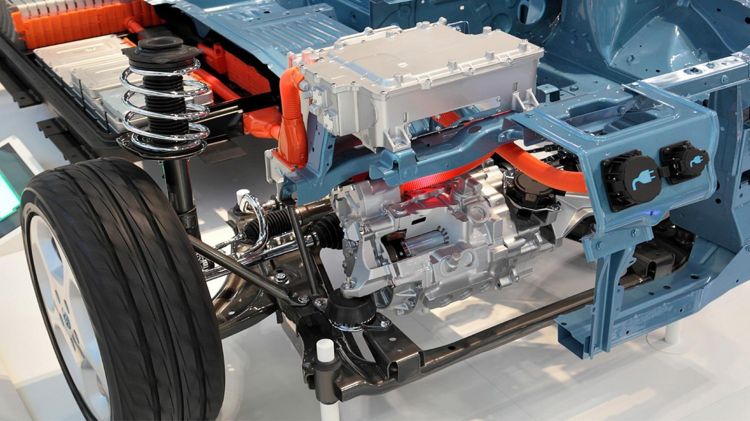

BTMS stands for Battery Thermal Management System and it is the device in electric cars developed to monitor and optimize the thermal state of batteries. In other words, it is responsible for managing and dissipating the heat generated during the electrochemical processes that occur in the battery cells.

This allows the battery to work safely and efficiently. The objective of the BTMS is to prevent the battery from deteriorating rapidly, which it achieves by managing the heat generated by its components so that it can function in optimal temperature conditions.

Battery temperature is a critical factor for battery operating performance. Specifically, charge/discharge capacity can be strongly influenced by temperature.

What are the main BTMS thermal management systems?

When selecting a BTMS for an EV battery pack, you will find that there is more than one alternative. BTMS thermal management systems are classified into:

- BTMS active.

- Passive BTMS.

- Hybrid BTMS.

What is active BTMS?

The active BTMS are those based on forced air or refrigerant, and are currently the most used in electric cars. For example, in electric cars Toyota I know use fans that circulate cool through the battery cells.

Tesla uses a cooling fluid through channels that are in direct contact with the cells.. When liquid refrigerants are used, they can be in direct contact with the cells or circulate inside the pipes and act indirectly.

Advantage:

- Relatively simple design, especially those based on forced air.

- High efficiency by keeping the batteries in the desired temperature range.

Disadvantages:

- High operating costs of plants based on forced air.

- Low efficiency in achieving temperature homogeneity between cells.

- There may be leaks in liquid based systems.

- Occupied volume and complexity of liquid-based systems.

What is passive BTMS?

passive systems they are an alternative to active BTMS, and outweigh their drawbacks by far. These types of systems are not currently implemented in EVs, but they are gaining in importance due to their operational advantages. Among the passive BTMS, those that change phase (PCM) and those with heat pipes (HP) stand out.

In the PCM can explore the high energies associated with phase changes that occur at nearly constant temperature. Paraffins, fatty acids and hydrated salts are the most studied compounds. PCMs have low thermal conductivity.

HPs are fluid-filled vacuum tubes that work by changing the liquid-vapor phase of the fluid. They have a flexible geometry, high thermal conductivity and practically zero maintenance.

What is hybrid BTMS?

For reap the benefits of active and passive thermal management BTMS systems, hybrid systems have emerged. These combine two or more of the alternatives described above. The most common combinations include the use of PCM with liquid cooling, PCM with forced air or PCM with heat pipes.

Among its objectives is achieve a good temperature distribution in the battery pack and the use of forced air or liquid cooling to evacuate the generated heat to the outside.

In PCMs with heat pipes, the aim is to improve heat transfer from the PCM to the outside of the cells. This causes cells to cool by natural convection.