The connecting rod has the mission of forming a link between the piston and the crankshaft, so it transmits power. It transforms the linear up and down movement of the piston into the circular movement of the crankshaft. It is a vital piece for the proper functioning of many motor parts. A damaged connecting rod can cause serious engine problems. Known whatWhat is the connecting rod of an engine, what are its parts, functions and types

What is the connecting rod?

The connecting rod is the part of a piston engine responsible for connecting the piston to the crankshaft. Together with the crank, the connecting rod transforms the rectilinear movement of the piston into the rotation of the crankshaft. The connecting rod is an important part for transmitting compression and traction forces to the piston. In a Internal combustion engine allows pivoting at the piston end and rotating at the shaft end. This engine component is difficult to lubricate. So good design and manufacturing is vital.

parts of a connecting rod

The connecting rods are made up of the following parts:

- small end: It is the end where the connecting rod joins the face of the piston pin, known as the small end of the connecting rod.

- big butt– This is the end where the connecting rod meets the pin side of the crankshaft, known as the big end of the connecting rod.

- hub bearing: The two ends of the connecting rod are fixed with a hub bearing. A phosphor bronze bushing has a solid eye attached to the small end of the connecting rod. The large end is attached to the crankpin. The end is split into two parts and fits over the crankshaft bearing bushing.

- Bearing insert: the big end of the connecting rod has a bearing insert connected to the bearing cap, known as the bearing insert. These are built in two parts that fit together inside the crankshaft. It is the position at which the connecting rod travels along the reverse direction.

- bolt and nut: After the connecting rod is adjusted with the crank at the bottom, both sides of the large ends are fastened with bolts and nuts. Once all these components are combined, the connecting rod is ready to use.

- Stem: Each of the bolts and nuts are used to connect the connecting rod and bearing cap. When a section beam is applied, it is known as a stem. The section of the rod can have a rectangular, tubular and circular shape.

- wrist pin: The engine piston is connected to the connecting rod with the help of a hardened steel hollow tube, it is known as a wrist pin, or gudgeon pin. The pin passes through the short end of the connecting rod and rotates on the meshed piston.

- Piston: the piston is connected to the crankshaft with the help of a connecting rod, it is regularly shortened to the connecting rod. The function of the piston is to serve as a mobile plug in the cylinder, forming the bottom of the combustion chamber.

- bearing cap– The housing bearings have a wear fit, although it controls operation, and the side clearance allows the bearing cap to be properly pressed.

Construction and Function of the Connecting Rod

The connecting rod transforms the linear up and down motion of the piston into the circular motion of the crankshaft, thus it is subject to tension, compression, bending, and buckling. The connecting rod is located on the crankshaft pin with a plain bearing. The connecting rod is usually hollow and has an internal cast oil passage to lubricate the gudgeon pin.

The connecting rods are made from microalloyed steels, sintered metals, high-quality aluminum, CFRP and titanium (for high-performance engines. In order to offer minimal weight and high resistance.

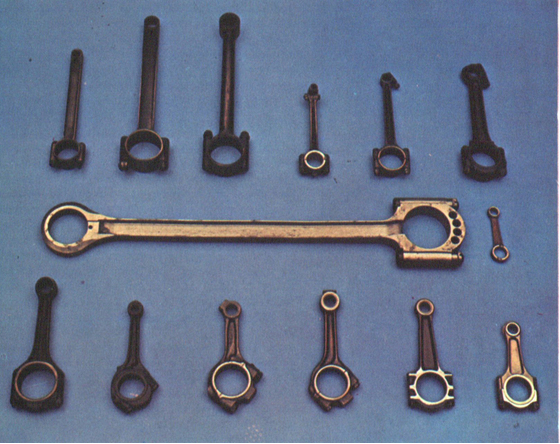

connecting rod types

There are several types of connecting rods that can be used in various engines, we start with:

1. Smooth type temples

It is a simple type of connecting rod used in inline and opposed engines. The large end of the connecting rod is attached to the crankpin with a bearing cap. The cap is attached with a bolt or stud at the end of the connecting rod. The connecting rod must be replaced in the same cylinder and relative position to maintain proper fit and balance.

2. Fork rods and blade

These types of connecting rods are used in V-twin motorcycle engines and V12 aircraft engines. In each pair of engine cylinders, a yoke rod splits into two parts at the large end and a knife rod tapers from the opposite cylinder to insert into the gap and into the yoke. The blade rod runs out of the bearing sleeve, not in the crankpin. Which leads to the two rods moving back and forth, reducing the force on the bearing and surface speed.

3. Master and slave rods

They are usually used in radial engines, the piston consists of a master connecting rod connected to the crankshaft. Other pistons connect to the connecting rods and to the rings around the master connecting rod. The disadvantages of the master and slave connecting rods are due to the fact that the stroke of the slave piston is slightly greater than that of the master piston, increasing vibration in the V engine.

4. Billet rods

They are used in high-speed cars. Billet connecting rods are made from steel or aluminum and are lighter, stronger and offer longer life.

5. Cast rods

It is the type of connecting rod preferred by manufacturers, because it can support the load of a standard engine. They are also cheap to produce, they cannot be used in high power applications. They have a visible seam down the middle that separates them from the forged type.

6. Forged rods

Certain connecting rods are manufactured by forging. These connecting rods are built by forcing a grain of material to the shape of the end. The material can be alloy steel (chrome and nickel) or aluminum. They increase the resistance of the connecting rod.

7. Driven metal connecting rods

This type is made with power metal, it is a mixture based on metallic powder that is pressed into the mold and heated at a high temperature. It becomes a solid shape.

connecting rod failure

The failure of a connecting rod, is generally known as “thrown a connecting rod” being one of the main serious causes in the car engine, which leads to the broken connecting rod destroying the side of the crankcase and finally the crankcase. engine has no repair.

Common reasons for connecting rod failure are due to traction problems due to high engine speeds, the force of impact when the piston hits a valve, connecting rod bearing failure occurs from lack of lubrication or incorrect connecting rod seating. .

Writing Gossipvehicle